Mg Road, Pondicherry

- GST NO. : 34AAFCM2672L1Z9

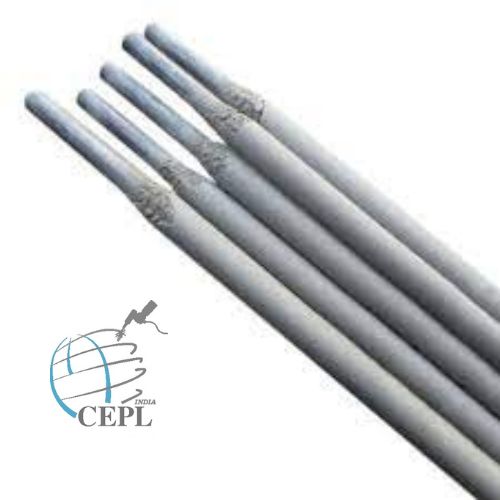

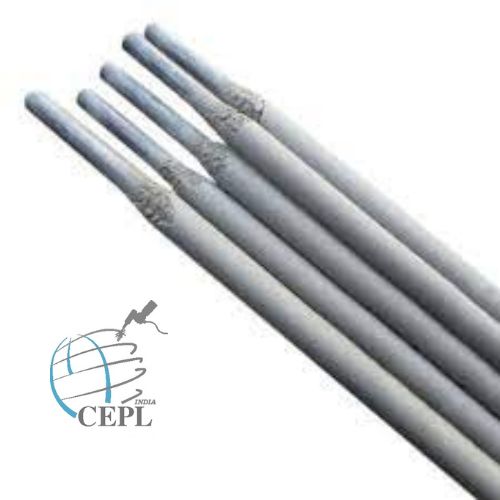

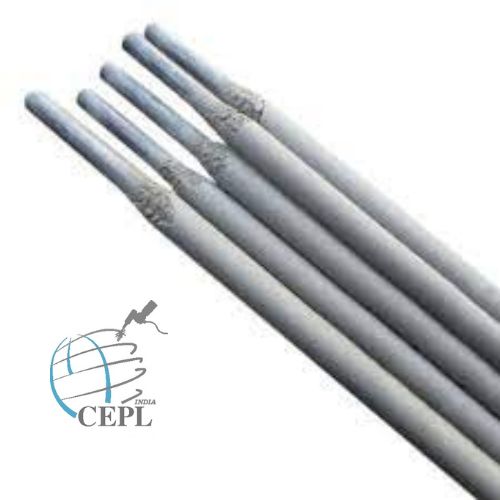

High Carbon Hardfacing Electrode

Leading Manufacturers, Exporters and Wholesaler of Centa ER 01 Manganese Hardfacing Welding Electrodes, Centa ER 02 Hardfacing Welding Electrodes, Centa ER 03 Hardfacing Welding Electrodes, Centa ER 05 Hardfacing Welding Electrodes, Centa ER 08 Hardfacing Welding Electrodes, Centa ER04 Hardfacing Welding Electrodes, Centa ER06 Crc Hardfacing Welding Electrodes, Centa ER07 Hardfacing Niobium Carbide Welding Electrodes and Centa ER09 Hardfacing Complex Carbide Welding Electrodes from Pondicherry.

MOQ : 20 Kilogram

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CEPL ER 01 |

| Material | Welding Purpose |

| Finishing | Polished |

| Current Type | AC, DC |

| Application | Welding Purpose |

| Length | 4inch |

| Type | Arc Welding Electrodes |

| Diameter | 4mmx450mm |

| Thickness | 4mm |

| Country of Origin | India |

| Product Code | ER65 |

| Payment Terms | D/P, T/T |

| Delivery Time | 1 WEEK |

| Packaging Details | 20KGS PER BOX |

Preferred Buyer From

| Location | Worldwide |

HARDFACING WELDING ELECTRODES Building up on hadfield management steel ,Typical applications are rail sections ,Mantles, Hammers, Rolls , Bucket theeth , LipS , Rock crushers Jaw crushers , Couplings, Spindles Excavators, Axles Rail points and crossings. Work Harden Application with 12 to 14% MN

MOQ : 20 Kilogram

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CEPL ER02 |

| Material | Welding Purpose |

| Finishing | Polished |

| Current Type | AC, DC |

| Condition | New |

| Application | Welding Purpose |

| Length | 4inch |

| Type | Arc Welding Electrodes |

| Diameter | 4x450mm |

| Thickness | 4mm |

| Country of Origin | India |

| Product Code | ER02 |

| Payment Terms | D/P, T/T |

| Delivery Time | 1 WEEK |

| Packaging Details | 20 KG PER BOX |

Preferred Buyer From

| Location | Worldwide |

HARDFACING WELDING ELECRODES Rutilebased flux cored wire mainly for crusher hammer •Rolls rail points and crossing ,Crane whee , Ingot tongs , Couplings, Spindles Excavators, Axles Rail points and crossings , Section where serve impact under heavy load Work hardening type for joining and building.

MOQ : 20 Kilogram

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CEPL ER 03 |

| Material | Welding Purpose |

| Finishing | Polished |

| Current Type | AC, DC |

| Condition | New |

| Application | Welding Purpose |

| Length | 450mm |

| Type | Arc Welding Electrodes |

| Diameter | 5mmx450mm |

| Thickness | 5mm |

| Country of Origin | India |

| Product Code | ER03 |

| Payment Terms | D/P, T/T |

| Delivery Time | 1 WEEK |

| Packaging Details | 20KGS PER BOX |

Preferred Buyer From

| Location | Worldwide |

HARDFACING WELDING ELECTRODES A Low Alloy Steel Flux cored wire for mainly building up purpose on crane wheel , Steel shafts , Ingot tongs , Trunions Gears Undercarring of earthmoving equipment , Excavator pins , Rail points and crossings.

MOQ : 20 Kilogram

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CEPL ER05 |

| Material | Welding Purpose |

| Finishing | Polished |

| Current Type | AC, DC |

| Condition | New |

| Application | Welding Purpose |

| Length | 450mm |

| Type | Arc Welding Electrodes |

| Diameter | 5mmx450mm |

| Thickness | 5mm |

| Country of Origin | India |

| Product Code | ER05 |

| Payment Terms | D/P, T/T |

| Delivery Time | 1 WEEK |

| Packaging Details | 20 KGS PER BOX |

Preferred Buyer From

| Location | Worldwide |

HARDFACING WELDING ELECTRODES Easy to use flux cored wire having good abrasion and impact resistance with higher hardness , Crane wheel , Ingot tongs , Mainly used for bucket lips Teeth Undersides Cutting edges , Rail points and crossings .

MOQ : 20 Kilogram

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Finishing | Polished |

| Current Type | AC, DC |

| Application | Welding Purpose |

| Length | 3inch,4inch,5inch |

| Type | Resistance Welding Electrodes |

| Thickness | 3.15mm |

| Country of Origin | India |

| Product Code | ER08 |

| Port | Chennai |

| Payment Terms | D/P, T/T |

| Delivery Time | 1 Week |

| Packaging Details | 20 Kg per Box |

Preferred Buyer From

| Location | Worldwide |

HARDFACING WELDING ELECTRODES Rutile type heavy coating Air hardenable crack free deposit Non machinable Resistant to metal to metal wear , Good combination of abrasion and impact propriate Resistant of friction . Recommended buffer layer of tenalloy on hard base materila.

MOQ : 20 Kilogram

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CENTA |

| Material | Mild Steel |

| Current Type | AC, DC |

| Application | Welding Purpose |

| Length | 450mm |

| Type | Welding Electrodes, Hardfacing Rods |

| Thickness | 4mm |

| Country of Origin | India |

| Product Code | ER04 |

| Port | CHENNAI |

| Payment Terms | D/P, T/T |

| Delivery Time | 1 WEEK |

| Packaging Details | 20 KG PER BOX |

Preferred Buyer From

| Location | Worldwide |

HARDFACING WELDING ELECTRODES •Mainly used for hardfacing and buildup of tractor rollers , Idlers , Steel mill rolls , Ingot tongs , Earthmoving machinery components Mine carwheels , Couplings, Spindles Excavators, Axles Rail points and crossings.

MOQ : 20 Kilogram

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Current Type | AC, DC |

| Condition | New |

| Application | Welding Purpose |

| Length | 350mm |

| Type | Hardfacing Rods |

| Thickness | 4mm |

| Country of Origin | India |

| Product Code | ER06 |

| Payment Terms | D/P, T/T |

| Delivery Time | 1 WEEK |

| Packaging Details | 20 KGS PER BOX |

Preferred Buyer From

| Location | Worldwide |

HARDFACING CHROMIUM CARBIDE WELDING ELECTRODES Worn out Ni-Hard and high chrome crusher rolls ,Table liners,Tires, Gyratory crusher cones and mantles , Mining and earthmoving equipment .Catalyst pipes and bends Slurry pipes and valuebodies Dredgepump bodies Extruder screws, Blast furnacebells Shovel edges wearplates.

MOQ : 20 Kilogram

| Business Type | Manufacturer, Exporter, Supplier |

| Material | MILD STEEL |

| Finishing | Polished |

| Current Type | AC, DC |

| Condition | New |

| Application | Welding Purpose |

| Length | 3inch,4inch,5inch |

| Type | Resistance Welding Electrodes |

| Thickness | 3.15mm |

| Country of Origin | India |

| Brand Name | CEPL |

| Product Code | ER07 |

| Port | CHENNAI |

| Payment Terms | D/P, T/T |

| Delivery Time | 1 WEEK |

| Packaging Details | 20KGS PER BOX |

Preferred Buyer From

| Location | Worldwide |

HARDFACING Niobium Carbide WELDING ELECTRODES Crane wheel , Ingot tongs On Bucket teeth Mixer blades Jaw crusher, Hammer ,A Electrods having complex carbide in a tought matrix mainly used for sand and earthmoving equipment ,Excavators, Axles Rail points and crossings. Electrode is designed for high Hardness, Abrasion and impact.

MOQ : 20 Kilogram

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CEPL |

| Material | Mild Steel |

| Finishing | Polished |

| Current Type | AC, DC |

| Condition | New |

| Application | Welding Purpose |

| Length | 3inch,4inch,5inch |

| Thickness | 4mm |

| Country of Origin | India |

| Product Code | ER09 |

| Port | Chennai |

| Payment Terms | D/P, T/T |

| Delivery Time | 1 Week |

| Packaging Details | 20 KGS PER BOX |

Preferred Buyer From

| Location | Worldwide |

HARDFACING Complex Carbide WELDING ELECTRODES A Electrode having complex carbide in a tough matrix mainly used for sand and earthmoving ,On bucket teeth , Ingot tongs , Mixer blades Pulleys, Shafts , Couplings, Spindles Rail points and crossings , Lips , Hammer , Rolls. High Heat Resistance up to 1000 Degree